- Independent study shows recycled graphite from Ascend Elements performs as well as virgin material

- Hydro-to-Anode® process technology developed by Ascend Elements and Koura recovers 99.9% pure graphite from recycled lithium-ion batteries

WESTBOROUGH, Mass., (November 1, 2023) China is a graphite powerhouse, but a new graphite recycling technology promises to give the West an alternate source of battery-grade anode material – one that performs just as well as virgin graphite.

According to Benchmark Minerals, China produces more than 70% of the world’s graphite – a critical material used in electric vehicle batteries – so when Beijing recently announced new limits on graphite exports, the West’s electric vehicle industry took notice.

Reuters and other news organizations have reported that the move is a response to U.S. limitations on the export of advanced artificial intelligence chips to China. Whatever the cause, graphite shortages would undoubtedly slow down America’s fast-growing lithium-ion battery industry.

Graphite is the largest single component in an EV battery and usually makes up about 25-28% of the battery, according to Benchmark Minerals. Given the emerging trade wars between China and the United States, EV OEMs and battery manufacturers are increasingly looking for alternatives to graphite, including advanced graphite recycling.

“We’re rethinking the way we use the planet’s resources and reaching higher to recover the maximum value in end-of-life lithium-ion batteries,” said Mike O’Kronley, CEO of Ascend Elements. “Graphite recycling is nothing new, but traditional graphite recycling methods do not produce a battery-grade product. The graphite recovered in most battery recycling processes is typically of a lower purity and must be used in non-battery applications. Our Hydro-to-Anode® process can produce 99.9% pure graphite, which even exceeds battery-grade requirements. It’s a game changer for the industry.”

Perfect Timing

It would be difficult to imagine a better time to announce a new graphite recycling venture. Ascend Elements has been working with Orbia subsidiary Koura for several years to develop the patented Hydro-to-Anode® process. Ascend first introduced the novel technology in February 2022. Then, on October 17, 2023, Ascend and Koura announced they are exploring joint commercialization of the advanced graphite recycling process and discussing plans to build an advanced graphite recycling facility in the United States. Just three days later, China announced its plans to limit graphite exports.

“Sometimes the timing works out in your favor,” said Eric Gratz, Ph.D., co-founder and chief technology officer at Ascend Elements. “Commercialization of this innovative technology will provide a new source of battery-grade anode materials for North America’s fast-growing electric vehicle battery industry. Of course, graphite recycling alone won’t meet the EV industry’s demand for anode material, but it will be an important part of the mix.”

The industry is also exploring the use of other anode materials like synthetic graphite, silicon, tin, aluminum, and lithium metal.

Until now, Ascend Elements has focused on producing engineered cathode materials from recycled lithium-ion batteries, primarily cathode precursor (pCAM) and cathode active materials (CAM), but the ability to recover graphite for use in batteries improves the economics of battery recycling and further minimizes the need for mining. Additionally, graphite processed in the United States is compliant with Inflation Reduction Act (IRA) requirements for electric vehicles to qualify for the 30D tax credit. O’Kronley believes that fact alone will help increase demand for recycled graphite in the coming years.

Equal Performance

How does recycled graphite from Ascend Elements match up against virgin material? Independent C-rate tests of NMC 622 pouch cells show that our recycled graphite performs as well as virgin material. And why wouldn’t it? Ascend Elements’ Hydro-to-Anode® graphite is 99.9% pure, battery grade graphite anode material.

Let’s take a closer look at the test results. First off, C-rate is a unit of measurement used by battery engineers to measure how fast a battery cell can be charged or discharged relative to its maximum capacity.

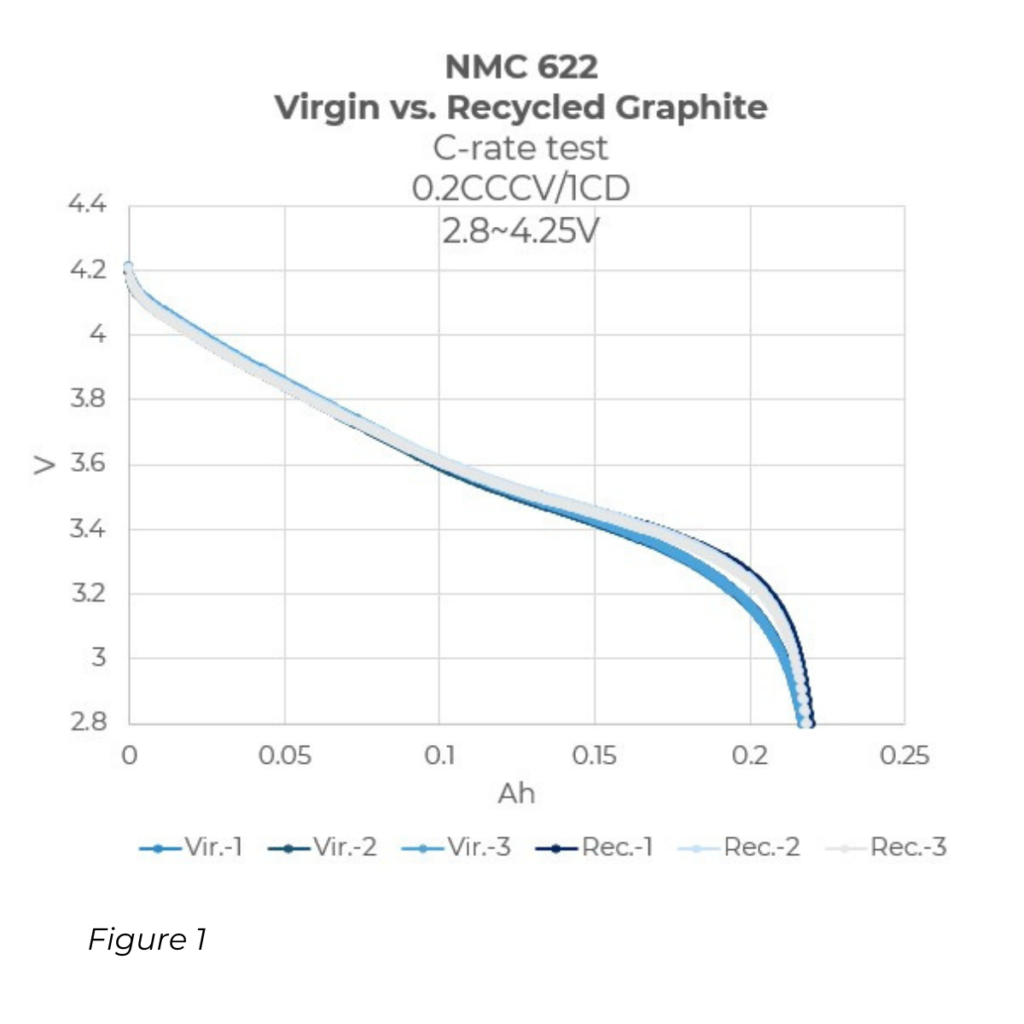

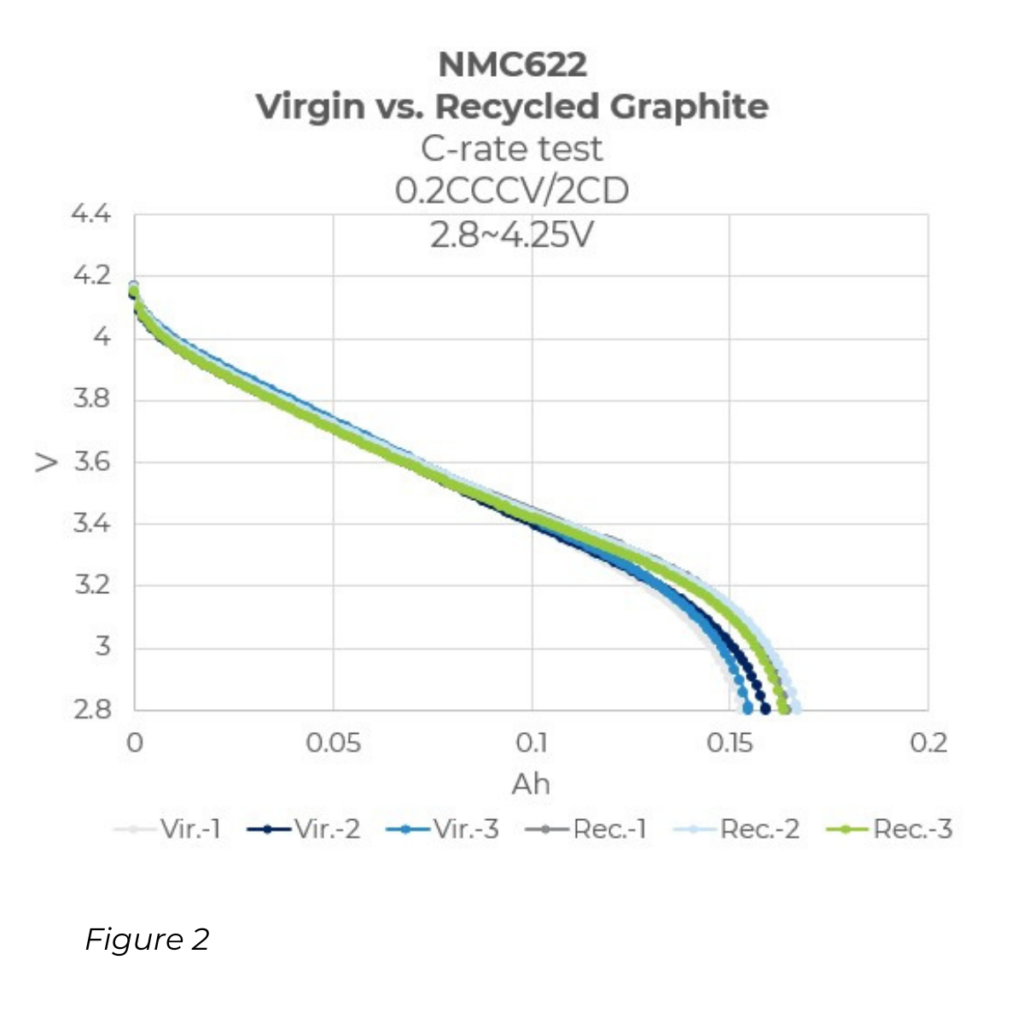

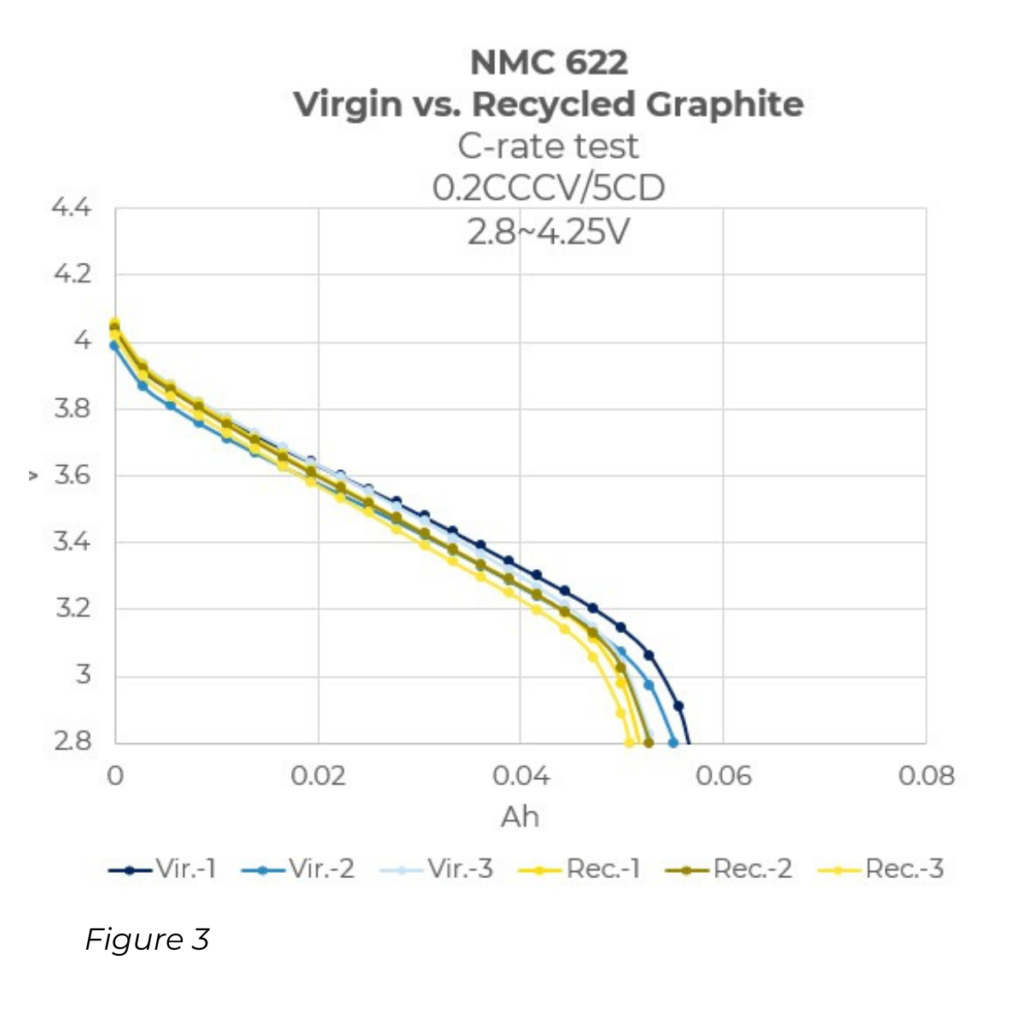

The graphs below compare the performance of Hydro-to-Anode® recycled material vs. virgin graphite as observed in identical NMC 622 pouch cells. The tests were performed by an independent laboratory. Figure 1 compares performance at 1C. Figure 2 shows performance comparison at 2C. Figure 3 shows performance of cells at 5C. Performance of the anode material is nearly identical in all tests, whether the graphite is new or recycled.

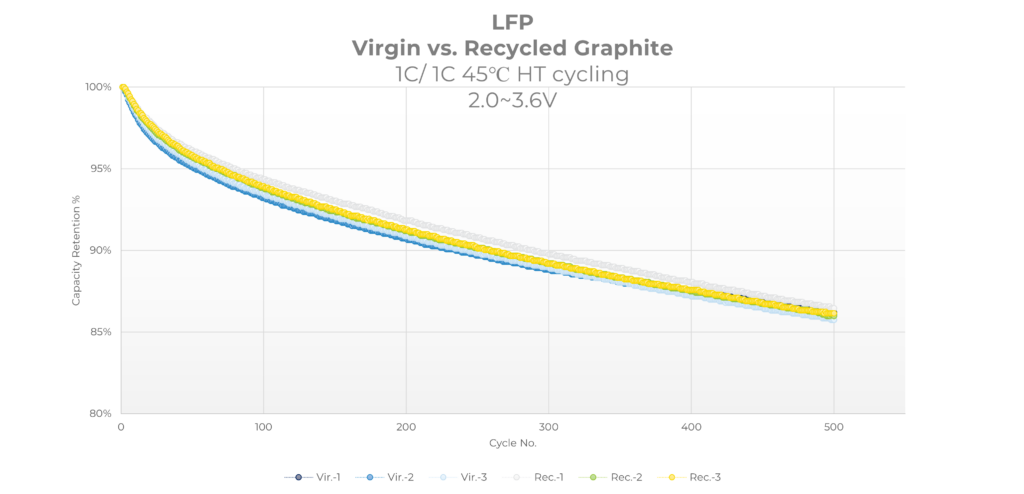

Figure 4 shows performance of recycled graphite in LFP pouch cells cycling at high temperature.

“That’s really the beauty of this process,” said Dr. Eric Gratz. “We’ve been able to recover and purify a battery-grade anode material that works just as well or better than virgin material with only a fraction of the carbon footprint created during mining. From an environmental and climate impact perspective, it absolutely makes sense to recycle and reuse the graphite in used lithium-ion batteries.”

While graphite recycling won’t replace mining anytime soon, it is bound to become an important part of America’s graphite supply chain. Ascend Elements and Koura are currently in discussions to supply IRA-compliant, battery-grade graphite to several electric vehicle original equipment manufacturers (OEMs) and battery manufacturers.