Ascend Elements Appoints John Swiger as Chief Financial Officer

Westborough, Mass. (July 8, 2025) Ascend Elements recently appointed John Swiger to the position of Chief Financial Officer (CFO). John replaces Andy Aberdale, who had

Beyond lithium-ion battery recycling, Ascend Elements is North America's top manufacturer of sustainable, engineered cathode precursor (pCAM) and recycled lithium carbonate (Li2CO3).

Thomas Frey, APR

+1-857-675-1653 office

[email protected]

Westborough, Mass. (July 8, 2025) Ascend Elements recently appointed John Swiger to the position of Chief Financial Officer (CFO). John replaces Andy Aberdale, who had

Westborough, Mass. (July 2, 2025) Ascend Elements recently appointed Deacon Powell to the position of General Counsel. He serves on the company’s Executive Leadership Team

Ascend Elements was founded in 2015 on the principles of sustainability. Our co-founders discovered a new way to recycle lithium-ion batteries and return critical battery

Cash subsidy valued at up to 1.22 billion PLN is one of the largest grants ever offered by Poland’s Ministry of Economic Development and Technology

An independently reviewed Life Cycle Assessment of Ascend Elements’ NMC 9.5.5 pCAM product finds a 49% reduction in carbon dioxide and 26% reduction in particulate

U.S.-based lithium-ion battery materials company is evolving from a R&D startup to commercial-scale manufacturer of domestic battery materials WESTBOROUGH, Mass., (March 20, 2025)— Ascend Elements,

A separate $316M U.S. DOE grant to Ascend Elements for pCAM infrastructure remains active to help fund construction of the Apex 1 project in Hopkinsville,

New Lithium Recovery Line at Covington, Ga. Battery Recycling Facility to Produce Up to 3,000 Metric Tons of Lithium Carbonate (Li2CO3) Annually COVINGTON, Ga., (December

Company recognized by Reuters Events alongside SK On and Polestar for “driving sustainability, zero emissions and net-zero goals.” Ascend Elements was recognized in the Reducing

Federal funds to support construction of U.S. infrastructure for the recovery and purification of graphite from used lithium-ion batteries. Ascend Elements and Koura Global, an

EV battery industry leaders and local officials joined Elemental Strategic Metals and Ascend Elements in Zawiercie, Poland to celebrate the grand opening of Europe’s newest

As construction of America’s first commercial-scale pCAM manufacturing plant continues, our engineers and artists are re-imagining the future state of the 150-acre campus.

The Science Based Target Initiative (SBTi) has recognized Ascend Elements’ commitment to set near-term and net-zero company-wide emissions reductions in line with climate science. This is the first step in the company’s decarbonization journey with SBTi.

The terms “circularity” and “closed loop” are often used to describe battery recycling processes like pyrometallurgy and hydrometallurgy, but these traditional recycling processes are just the first steps in any round-trip journey of battery materials. Ascend Elements CEO Mike O’Kronley discusses EV battery circularity

DQS Inc., an independent certification body, recently certified Ascend Elements’ electric vehicle (EV) battery recycling facility in Covington, Ga. to the ISO 9001:2015 standard for Quality Management Systems.

Ascend Elements won the “Recycler of the Year” award at the inaugural Fastmarkets Voltas Awards on June 25 in Las Vegas. The Voltas Awards recognize and celebrate pioneering companies, leaders and innovators who have demonstrated excellence

Recycling Today Editorial Director DeAnne Toto interviews Ascend Elements CEO Mike O’Kronley on June 18, 2024 during the Battery and Critical Metals Conference in Atlanta.

In a milestone for the U.S. battery materials industry, Ascend Elements recently shipped decarbonized cathode materials to Freudenberg e-Power Systems, one of the world’s leading suppliers of emissions-neutral energy solutions for heavy-duty applications.

Ascend Elements co-founders Eric Gratz, Ph.D. and Yan Wang, Ph.D. have been named to the third annual Tech Power Players 50, a list of the most influential – and interesting – people in the New England technology scene, as ranked by The Boston Globe’s business journalists and an

external advisory.

A new agreement between Ascend Elements and Call2Recycle will bring customized electric vehicle (EV) battery management, logistics and recycling services to automotive dealerships, recyclers, and repair facilities.

Ascend Elements recently selected EY US to develop a complex logistics simulation model for its 1 million-square-foot Apex 1 EV battery materials (pCAM) manufacturing facility currently under construction in Hopkinsville, Kentucky.

Massachusetts Gov. Maura Healey and Secretary of Economic Development Yvonne Hao visited the Ascend Elements R&D Center in Westborough, Mass. on April 16.

New joint venture will own and operate an advanced Li-ion EV battery recycling facility in Zawiercie, Poland, with another planned in central Germany.

For the second year in a row, Ascend Elements has been named to Fast Company’s prestigious list of the World’s Most Innovative Companies.

Ascend Elements has been named to TIME Magazine’s Top Green Tech Companies of 2024 list.

Ascend Elements today announced it has raised $162 million in new equity investments. Latest funding adds to the company’s recent $542 million equity round for a 12-month funding total of $704 million

Ascend Elements can today manufacture new EV battery material at a 49% reduction in carbon emissions compared to traditional cathode manufacturing processes that rely on primary materials from mining. By 2030, the company aims to achieve a 90% reduction in carbon footprint.

Ascend Elements team members and partners in Hopkinsville, Ky. celebrated a major milestone in the construction of North America’s first electric vehicle battery cathode precursor (pCAM) manufacturing facility this week.

2023 has been a transformational year at Ascend Elements — from the grand opening of North America’s largest EV battery recycling facility to a $1B contracted sale of sustainable pCAM for use in American-made electric vehicles.

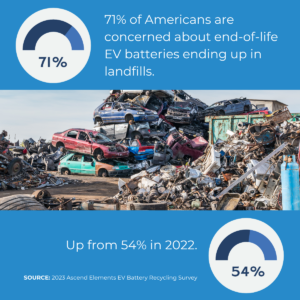

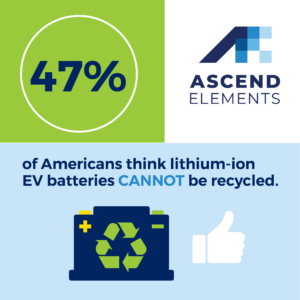

As the electric vehicle (EV) market continues to grow in the United States, Americans are increasingly concerned about what will happen to all those lithium-ion EV batteries when they reach end of life – even though the EV battery recycling industry is booming.

China is a graphite powerhouse, but a new graphite recycling technology promises to give the West an alternate source of battery-grade anode material – one that performs just as well as virgin graphite.

Patented Hydro-to-Anode® Graphite Recycling Technology Produces 99.9% Pure Graphite from Used Lithium-ion Batteries WESTBOROUGH, Mass., (October 17, 2023) — Ascend Elements, a U.S.-based manufacturer of

Heavy-duty electric trucks, buses, and maritime vessels in North America and Europe may soon be powered by recycled battery materials. Ascend Elements, a U.S.-based manufacturer of sustainable, engineered battery materials, today announced a contract to engineer sustainable cathode active material (CAM) for Freudenberg e-Power Systems.

Latest funding round is one of the largest U.S. cleantech equity private placements of 2023 to date.

Up to $5 billion deal signals a shift in worldwide battery material supply chains as Ascend Elements builds one of North America’s first commercial-scale NMC pCAM manufacturing facilities in southwest Kentucky.

Ascend Elements’ Hydro-to-Cathode® direct precursor synthesis technology was recognized by Fast Company as one of North America’s top 20 World Changing Ideas for 2023.

CEO Mike O’Kronley was recognized on the annual Worcester Business Journal Power 50 list for 2023.

Company recognized in the Clean Energy category at prestigious celebration of innovation. Congratulations to our co-founder Eric Gratz, Ph.D. and his sustainable cathode engineering team for taking home

Ascend Elements celebrated the grand opening of its first commercial-scale lithium-ion battery recycling facility this week.

Ascend Elements to supply Koura Global with up to 5,000 metric tons of recycled lithium carbonate per year for new electric vehicle batteries.

Ascend Elements has been named to Fast Company’s prestigious annual list of the World’s Most Innovative Companies for 2023. The company is ranked No. 3 in the Energy and Sustainability category.

Ascend Elements today announced a basic agreement with Honda Motor Co., Ltd. to collaborate on stable procurement of recycled lithium-ion battery materials for Honda electric vehicles in North America.

Ascend Elements has been selected as The Cleanie Awards® Silver place winner for Pioneer in New Technology- Battery Category for its innovative Hydro-to-Cathode™ direct precursor

Ascend Elements, a U.S.-based battery recycling and engineered materials company, was today named to the Global Cleantech 100 list for the second year in a row. The Cleantech Group considers the 100 companies on the list to be the top innovators in the climate tech space,

Ascend Elements wins Gold for Battery Logistics and Silver for Electric Vehicle category of the 2023 Automotive & Transportation Merit Awards.

The people of Ascend Elements accomplished great things in 2022. We started the year as Battery Resourcers with about 60 employees and we are ending the year as Ascend Elements with more than 170 team members! Take a look back at the past 12 months.

Electric vehicle battery recycling is a booming industry – and the key to lowering the carbon footprint of EVs – but nearly half of Americans mistakenly believe lithium-ion EV batteries are destined for landfills.

Business Insider: The burgeoning battery-recycling startup Ascend Elements is sitting on a fresh $800 million. Founded in 2015, Ascend Elements says its tech can get car companies and their battery-makers the materials they need at a lower cost

Ascend Elements, a U.S.-based engineered materials and lithium-ion battery recycling company, today announced it has secured $300 million in equity and debt financing, including $200 million in Series C equity investments from an international group of strategic and financial investors.

Ascend Elements began construction of its largest electric vehicle battery recycling and engineered materials manufacturing facility with a ceremonial groundbreaking today. Leaders of the fast-growing startup were joined by Gov. Andy Beshear, local business and community leaders, and EV battery industry executives during the midday

Ascend Elements announced today that it has been awarded grants from the U.S. Department of Energy’s Bipartisan Infrastructure Law (BIL) Battery Materials Processing and Battery Manufacturing Initiative. The awards, totaling $480M in matching funds

Ascend Elements and EcoPro Group today announced a memorandum of understanding (MOU) agreement to cooperate in the development, qualification, and integration of recycled battery materials into EcoPro’s cathode products. The agreement paves way for a sustainable, closed-loop supply of domestic lithium-ion battery materials in the United States.

Take a look inside Base 1, Ascend Elements’ first commercial-scale EV battery recycling facility in Covington, Georgia. When fully operational in Q4 2022, the facility will recycle 30,000 metric tons of lithium-ion batteries and manufacturing scrap a year. That’s about 70,000 electric vehicle batteries per year

Jaguar Land Rover and South Korean conglomerate SK Group are among the investors putting more than $300 million into Ascend Elements, a startup that aims to serve an emerging center of battery production in the Southeastern U.S.

SK ecoplant’s $50 million investment will help accelerate the commercialization of Ascend Elements’ innovative Hydro-to-Cathode™ direct precursor synthesis technology, which quickly and efficiently transforms recycled lithium-ion batteries and manufacturing scrap into high-performance, customized EV battery cathode precursor and cathode active materials.

Ascend Elements today announced plans to invest up to $1 billion to build a sustainable lithium-ion battery materials facility in Hopkinsville, Ky.,

Building a domestic EV battery manufacturing and recycling infrastructure in the United States is essential to America’s long-term energy independence.

Ascend Elements CTO Eric Gratz, Ph.D. was recently recognized by Business Insider as an EV industry “Power Player.” The annual list recognizes the 30 most influential leaders in the electric vehicle and Li-ion battery industries.

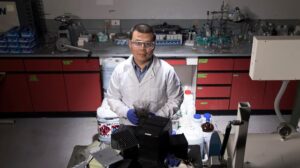

“After handing me a pair of safety goggles, Ascend Elements’ co-founder and chief technology officer, Eric Gratz, shows me the works. Shouting over the constant whine of a generator, he ushers me into a high-ceilinged space dominated by a dozen interconnected tanks and machines.”

Ascend Elements CEO Mike O’Kronley answers questions on a wide variety of EV battery recycling topics

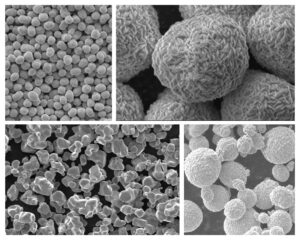

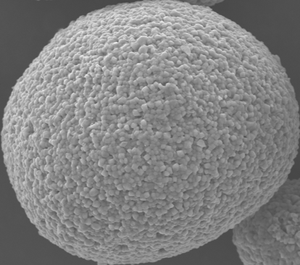

Beyond recovering 98% of critical elements in used lithium-ion batteries, Ascend Elements uses microstructure engineering techniques to adjust the elemental crystal structure of new cathode material to precise customer specifications

Massachusetts-based Ascend Elements, has developed a process to capture battery metals and formulate them into new battery materials, rather than just recycle whole components as competitors do. Ascend can then sell those materials directly to manufacturers.

Ascend Elements’ Covington, Georgia facility will recover 98% of battery materials and return critical elements to the battery supply chain.

Congratulations to Worcester Polytechnic Institute’s Todd Keiller and Ascend Elements co-founders Prof. Yan Wang and Eric Gratz for winning AUTM’s Better World Project award for 2022! This award program highlights the global impact

Ascend Elements, a vertically integrated lithium-ion battery recycling and engineered materials company and Koura, an Orbia business and one of the world’s largest producers of fluoroproducts and technologies

We are pleased to welcome Haixia Deng, Ph.D., to the Ascend Elements team. Dr. Deng will serve as Vice President of Cathode with responsibility for company’s development of customized cathode products.

Ascend Elements’ co-founder Yan Wang and his innovative Hydro-to-Cathode battery recycling process featured in Scientific American

WESTBOROUGH, Mass. (January 31, 2022) — Ascend Elements, the vertically integrated lithium-ion battery recycling and engineered-materials company previously known as Battery Resourcers, today announced it

An Automotive News TV segment featured Ascend Elements on January 25, 2022. First Shift host, Tom Worobec, explained automakers plan to spend $515 billion over the

WBUR Boston’s Bruce Gellerman visited Ascend Elements in Westborough, Mass. recently for an in-depth segment on lithium-ion battery recycling. The segment begins by identifying the

It’s not easy changing a company name. Between branding, signage, trademarks, banking, legal and IT system updates, there’s a lot of time and effort involved

WESTBOROUGH, Mass. (January 19, 2022) —Battery Resourcers, a vertically integrated lithium-ion battery recycling and engineered materials company, today changed its name to Ascend Elements as

Battery Resourcers, a vertically integrated lithium-ion battery recycling and engineered-materials company, was recently named to the annual Global Cleantech 100 list. The Cleantech Group considers

COVINGTON, Ga. (January 5, 2022) — Battery Resourcers, a vertically integrated lithium-ion battery recycling and engineeredmaterials company, today announced plans to open a commercial-scale, lithium-ion

Battery Resourcers, a startup developing a closed-loop process for recycling and manufacturing lithium-ion battery materials, was named the 2021 Rocket Ship Climate Tech Company of

Battery Resourcers, a startup that’s developing a closed-loop approach to lithium-ion battery materials, has raised $70 million in mid-round funding to scale its commercial operations

With a strategic facility conversion, paired with multiple expansions, the battery material and manufacturing company has increased its processing capacity for battery production. [Note: On

Worcester, Mass. (July 22, 2021) Battery Resourcers, a vertically integrated lithium-ion battery recycling and manufacturing company, today announced the appointment of Kelly Kay to its

Aria Alamalhodaei June 28, 2021 Honda said Monday it will sell its first electric SUV in North America in early 2024, part of the automaker’s

Worcester Polytechnic Institute (WPI) will expand its work on lithium-ion battery recycling and lead a team of academic and industry collaborators in a $2 million

Battery Resourcers, a vertically integrated lithium-ion battery recycling and manufacturing company, recently completed a $20 million Series B equity round with financing led by Orbia

WORCESTER, Mass., June 28, 2021 /PRNewswire/ — Battery Resourcers, a vertically integrated lithium-ion battery recycling and manufacturing company, today announced an agreement with American Honda

Request a Quote

Please use this form to request a quote from Ascend Elements. Thanks for your interest.